Rinnai’s Chris Goggin looks in detail at the cost savings in both time and energy costs that comes with effective scale protection to all systems. A case study of hotels is used to demonstrate the efficiency savings, but care home owners and managers will quickly see the parallels with their own business model.

Limescale within the heating & hot water systems at commercial sites across the UK is a common problem associated with hardwater areas. About 60% of mains water supplied in the UK is classified as ‘hard’ and this produces limescale deposits which reduce the efficiency of heating & water-heating appliances and systems. This means increased operating costs. Just 1.6mm of scale can reduce system efficiency by 12%. This leads to greater costs on energy fuels and site time through remedial works combatting the limescale.

The existence of limescale, in a heating & hot water system, simply adds a significant cost. These repercussions from limescale build up can have a lot of negative outcomes, but most importantly it has significant effects on reducing the efficiency of water heating technology, in turn increasing the amount of energy needed to be consumed to meet hot water demands within commercial buildings.

Limescale increases the energy consumed as it impedes the heat transfer efficiency of plate heat exchangers, water heaters, and other technologies, therefore, forcing this technology to input more energy to retain the same level of performance.

Limescale increases the energy consumed as it impedes the heat transfer efficiency of plate heat exchangers, water heaters, and other technologies, therefore, forcing this technology to input more energy to retain the same level of performance.

This report aims to highlight the expected operating expenditure (OPEX) and carbon production savings when installing scale protection, compared to various thicknesses of scale buildup within DHW systems.

Industry studies show the figures regarding the percentage increase in energy usage as the thickness of scale increases. The graph below demonstrates that energy usage increases by 7% with every 1mm of scale build up.

Just recently the Rinnai Technical Dept made a collective Case Study of three hotels – small, medium, and large.

- A small three star hotel with twenty-five rooms

- A medium four star hotel with seventy-five rooms

- A large five star hotel with 150 rooms

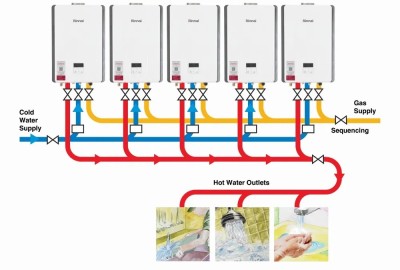

To conduct this study a gas system was sized for each archetype. The systems modeled for the sites are:

- Small hotel – 2 x N1600 + 300L storage

- Medium hotel – 6 x N1600 + 800L storage and

- Large hotel – 16 x N1600 + 2000L storage, respectively.

The purpose of comparing different sized hotels is to show how the expected OPEX and carbon production savings increase as the size of the commercial building increases. This shows that scale protection is important for every system in a hard water area, and that the importance of this protection increases as the system size and hot water demand increases.

For the three star small hotel measured over a 10-year period as the thickness of scale increases from having no limescale to having 4mm of limescale results in showing that for every mm increase in limescale, the carbon production increases by 14,978kgCO2. Therefore, if scale increased to 4mm, the system would produce an additional 59,912kgCO2 compared to a fully protected system.

The output is similar from an operating costs perspective. For every mm increase in scale thickness, the operating cost to run the DHW system, for a small 3 star hotel, increases by £3,200. While if the scale thickness increases up to 4mm, the increase in costs totals to £12,799 over a 10-year forecast period, which is a percentage increase of 28%.

The second case study looks at a medium sized hotel and a higher star rating, which suggests higher hot water demand. This increase in hot water demand along with increased scale thickness portrays even higher carbon production and operating costs differences compared to a fully protected DHW system.

Results here show that for every mm increase in scale within a DHW system, the increase in carbon production and operating costs is 40,864kgCO2 and £8,829, respectively. Therefore, when comparing a fully protected system to a system with a scale buildup of 4mm it shows forecasted carbon and OPEX savings of 163,465kgCO2 and £34,677 over a 10-year forecast period.

The final case study looks at the top of the range, large 4 star hotel, as means to highlight how important scale protection is as a site’s hot water demand grows. As seen by the graphics one & two, the increase in carbon and OPEX per mm of scale build up is 101,793kgCO2 and £21,820, respectively. Therefore, comparing a DHW with 4mm of scale to a fully protected system with no scale, the expected savings for an archetype hotel of this size for carbon and OPEX, over a 10-year period, are 401,049kgCO2 and £86,684, respectively.

IN summary – WHY prevent and protect from limescale build UP?

- Increases energy efficiency: Improves heat transfer, which will lead to lower fuel consumption.

- Lowers maintenance costs: Extends the life of equipment and reduces the need for manual cleaning.

- Improves water quality: Cleaner surfaces in pipes and fixtures lead to better water hygiene.

Rinnai offers a range of products preventing limescale build-up and has a close working partnership with AQUABION®, a patented galvanic and electrolytic solution in a self-cleaning package. In this process, minute amounts of high-purity zinc ions are released and react with calcite. Calcite crystals are modified into adhesion-neutral aragonite, which is simply discharged into the water.

Different to other water treatment units the patented AQUABION® operates without current, chemicals or magnets. The two swirling chambers each upstream and downstream agitates the water and is responsible for the self-cleaning effect of AQUABION® units themselves. AQUABION is both chemical and electricity free and is a fully recyclable water treatment system enabling both end users and water treatment providers to tackle the problems of limescale without impacting the environment. It serves as a viable alternative to a commercial water softener with its environmental benefits.

To find out more about how Rinnai can assist you with your hot water and heating system, please ask us a question.